Composite decking is a relatively new material that has revolutionised and opened up a whole new side of the decking industry.

Due to its rapid and enormous growth and company competition within the composite decking space, there are many beliefs and misconceptions around the appearance, cost, and performance of the material.

Here we look to tackle to basic facts and fiction around composite decking materials.

Appearance

Composite decking has come a long way since its inception more than 25 years ago. The first two generations of composite decking looked fake compared to wood due to incapability to create realistic colour tones or textures. These first two generations contained more plastic than wood which made it difficult to pass as timber.

The third generation of composite decking comes in an array of colours and textures that mimic the natural grain and beauty of timber. These are usually sold at a higher price point based on the complexity involved with putting a high amount of detail in composite boards to successfully replicate the look of timber.

There are still companies who sell second-generation composite decking, often at a lower price due to the nature of the material. It’s as simple as asking your supplier what generation of composite decking they carry. And if they don’t know you have got to wonder how knowledgeable is your supplier.

Variety

The colour pigmentation of composite decking is added at the time of manufacture, meaning home owners can get almost any colour they want, as long as they understand they can’t paint over the top.

As they are manufactured, composite boards can be extremely flexible to fit any home project needs, however they cannot be re-sanded, oiled, or stained to change their appearance once they are installed.

As there are a lot of composite manufacturers, there is also a variety of low-to-high performance composites. Some composite materials are superficially superior but don’t weather well under environmental conditions or heavy use.

High-performance composite capped boards from Trex® feature an added layer of protection against severe weather, heavy foot traffic, fading, mould and staining.

Cost

The more deliberate manufacturing process involved with the creation of composite decking boards often results in a higher price point than other easily available materials such as native timbers.

A decking board at double the price does not necessarily mean the cost of your deck will be double; the boards themselves are a smaller part of the larger project which includes the framework that it sits on as well as any necessary railings or stairs and labour.

The initial outlay cost for the material will be similar to some exotic woods but the majority of third-generation composite decking comes with warranties.

It’s also important to consider the long-term costs, such as maintenance which we’ll explore later. It’s safe to say that the ongoing costs of maintaining a composite deck are slight in comparison to other decking materials.

Environmental Impact

Composite decking is a man-made building product that is typically made from a combination of different materials that includes a mix of wood and plastic. Both the wood (which consists of industry by-products like sawdust, chips, and wood fibre) and the plastic can be made from virgin or recycled material.

The wood and plastic are combined with bonding agents, pigments, and stabilisers, then are heated and extruded into planks that are often (depending on the generation) made with a grain-like pattern to look like real wood.

Research your preferred composite decking manufacturer to learn how its products are produced. Trex® qualifies as one of the biggest plastic recyclers in the US by saving of material from landfill each year and making their deck boards from a blend of 95% recycled wood and plastic film.

Installation

Professional quality decking installation is crucial, as composite decking boards must be fitted correctly to reap the long-term benefits that the material can provide.

Over the lifetime of the deck, expenses for composite decking are likely to be lower. If installed incorrectly composite decking can sag and buckle, expanding and contracting with temperature changes which must be taken into consideration.

When installed correctly the deck will not warp, crack, splinter and, when your deck is installed, you can start enjoying it right away, without the need to stain or seal the deck.

Maintenance

One of the few threats to composite decking is mould growth in consistently wet and shady areas of the deck. Applying a mould barrier at the outset can prevent its development. In cases where it does develop homeowners can remove mould with special cleaners to not harm the surface.

It is best practice not to construct a new deck in an area of your home where it would be consistently moist and shady, regardless of the material used. Anything that sits outside in the elements for years on end is going to need some maintenance, but composite decking sits at the lower end of that scale.

Since it never needs stain or paint and is decay-resistant, it is recommended that owners only need to wash it 2-3 times a year with a hose and broom to prevent dirt build up.

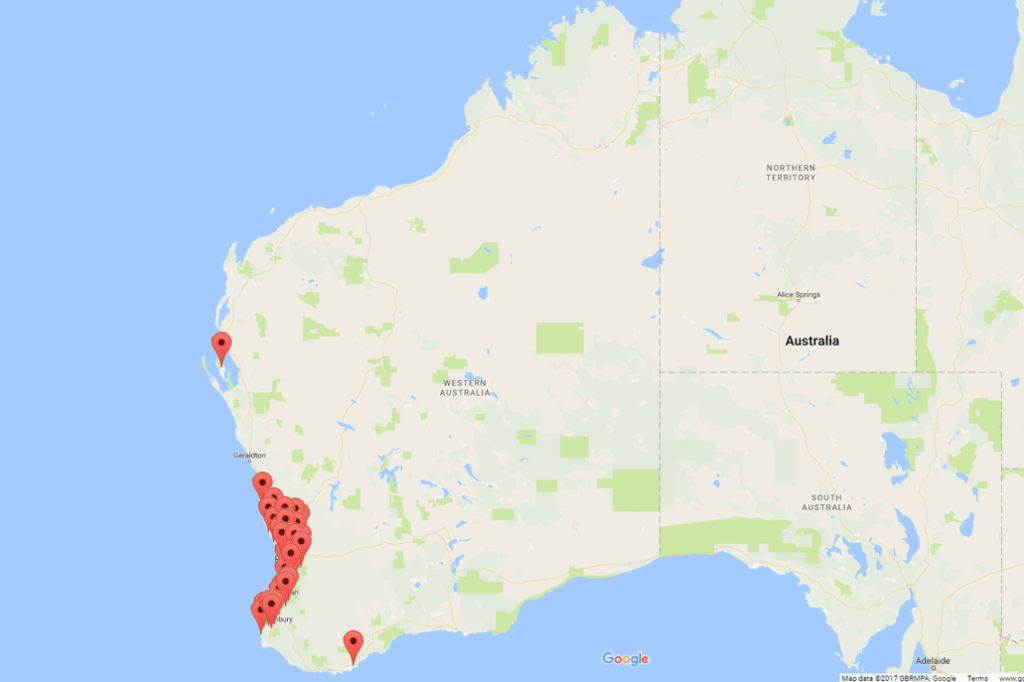

Decking Perth

Decking Perth are the best decking professionals in WA.

When adding outdoor decking on to your home, you want something that is going to last for years to come. This is exactly the kind of deck you will receive from Decking Perth.

We have highly skilled timber decking professional contractors, and certified installers here to help make your dream deck into a reality.

Want to learn more about composite decking and how it compares to timber decking? Check out Composite Decking vs Timber Decking now!